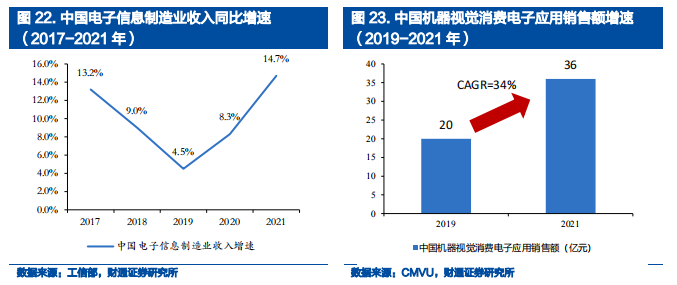

The global 3C electronics industry has transferred to developing countries, and the characteristics of high precision and fast replacement have boosted the iteration of machine vision technology. In 2021, the revenue of China's electronic information manufacturing industry increased by 14.7% year-on-year, gradually becoming the world's largest electronic information product manufacturing base. Due to the small size of components in the consumer electronics industry and high detection requirements, it is naturally suitable for the landing of machine vision systems, and its high-precision requirements have also reversely promoted the innovation of machine vision technology. In addition, the consumer electronics industry product life cycle is short, fast replacement, manufacturing enterprises need to frequently replace production line equipment, further increasing the demand for machine vision industry. According to CMVU statistics, from 2019 to 2021, China's machine vision sales growth rate in 3C electronics is as high as 34%. The penetration rate of machine vision in the 3C electronics industry is expected to continue to increase.

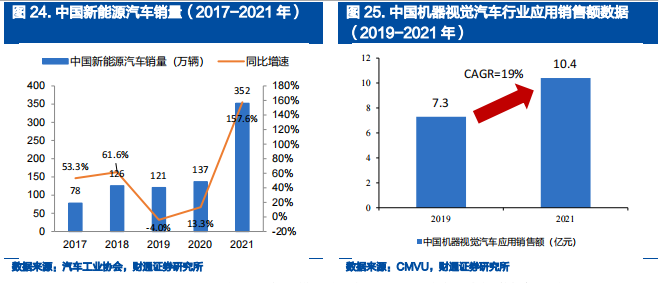

Smart cars are evolving into "large electronic products". In the field of automobile manufacturing, parts inspection, assembly verification inspection, glue detection and so on are inseparable from machine vision technology. The electrification and intelligence of the automotive industry will promote the evolution of automobiles into "large electronic products", and the industry will increase the demand for equipment with machine vision inspection technology. In 2021, China's new energy vehicle sales increased by 157.6% year-on-year to 3.521 million units, and the scale of the machine vision automotive industry has exceeded 1 billion yuan during the same period.

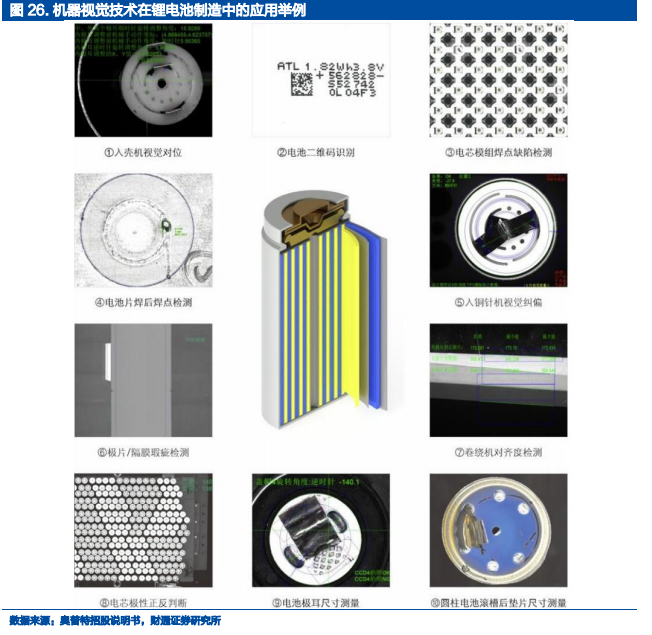

Lithium battery technology is complex, machine vision application scenarios are rich. Machine vision is mainly used in coating correction, size measurement, surface defect detection, size measurement, winding alignment and other links. It is mainly used in the welding quality inspection of bare cell pole ear folding, pole ear cutting debris, pole ear, inlet shell top cover and sealing nail, as well as the appearance inspection, size measurement, adhesive positioning, etc. Modules and PACK segments are mainly used in bottom blue glue, BUSBAR welds, side welds, full size modules and PACK inspection.

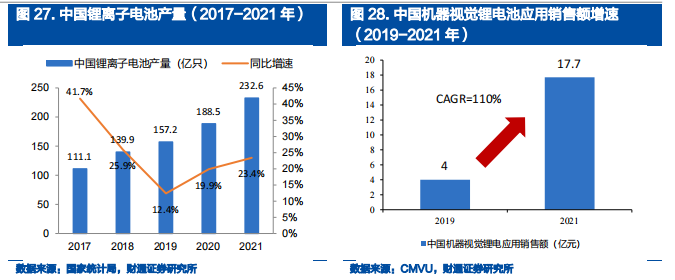

The vigorous development of new energy vehicles has driven the machine vision of the lithium battery industry to a blowout trend. Data from the National Bureau of Statistics show that in 2021, China's lithium battery production has reached 23.26 billion, an increase of 23.4%. According to GGII incomplete statistics, in 2021, China's power battery investment expansion projects (including raised investment projects), the total investment (including proposed investment) of more than 621.8 billion yuan, long-term planning of new capacity has exceeded 2.5TWh. The rapid increase of lithium battery production capacity has led to the rapid development of machine vision, and the market size will reach 1.77 billion yuan in 2021, with a CAGR of 110% from 2019 to 2021.

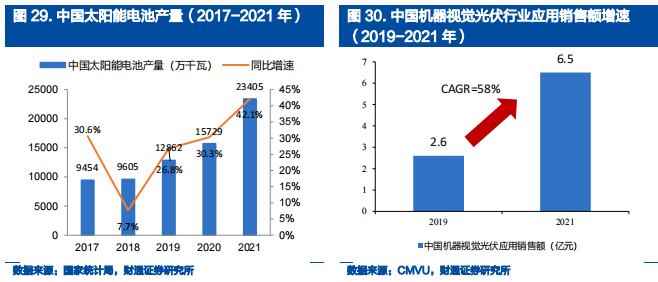

The rapid development of the photovoltaic industry has brought about an outbreak of demand for machine vision inspection. The production of photovoltaic cells may produce defects such as debris, hidden cracks, surface contamination, and bad electrodes. From 2018 to 2021, China's solar cell production CAGR reached 35%, with a year-on-year growth rate of 42% in 2021, and the industry ushered in an accelerated growth period. During the same period, the application scale of the photovoltaic industry driving machine vision rapidly increased from 260 million yuan in 2019 to 650 million yuan in 2021. CAGR is up to 58%.

The application direction of machine vision includes industrial grade and consumer grade, and the industry boundary tends to be blurred. According to data from the Machine Vision Alliance (CMVU), security and monitoring, logistics sorting and intelligent transportation for consumer machine vision account for only 17.0%, but their share is increasing year by year. With the commercial landing of AI and 5G technology, machine vision combined with 3D reconstruction, action/expression capture, rendering and other technologies can achieve the restoration of faces, expressions, actions, clothing, and build simulated realistic characters. In addition, technologies such as face recognition, action recognition, and object tracking can also be used to simulate human vision capabilities. Therefore, there is still room for machine vision in film and television, games, live broadcasting, cultural travel and other fields.

(文章来源:财通证券研究所)

TOP

TOP Contact

Contact

Product

Product