Chip wire-bonding defect inspection

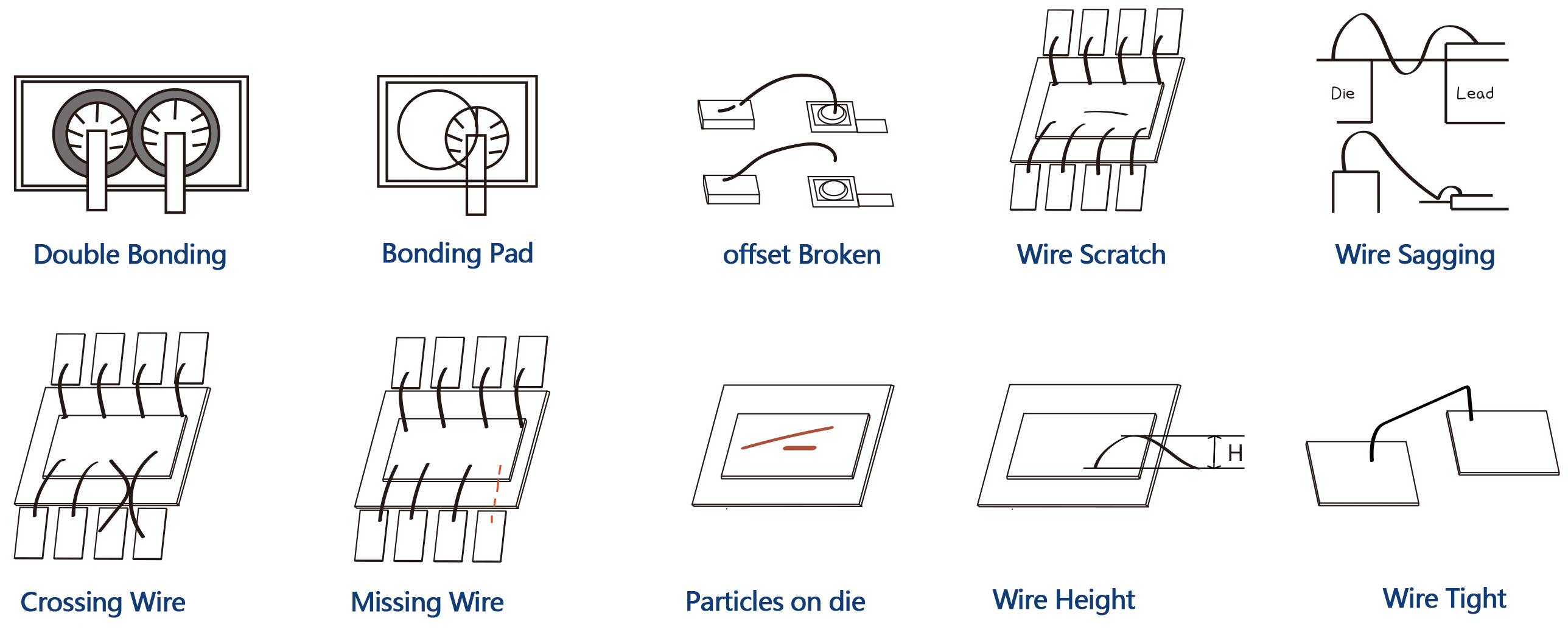

To inspect defects with wire-bonding by light field camera. It supports in-line inspection as a 3D vision camera. In order to improve production efficiency.

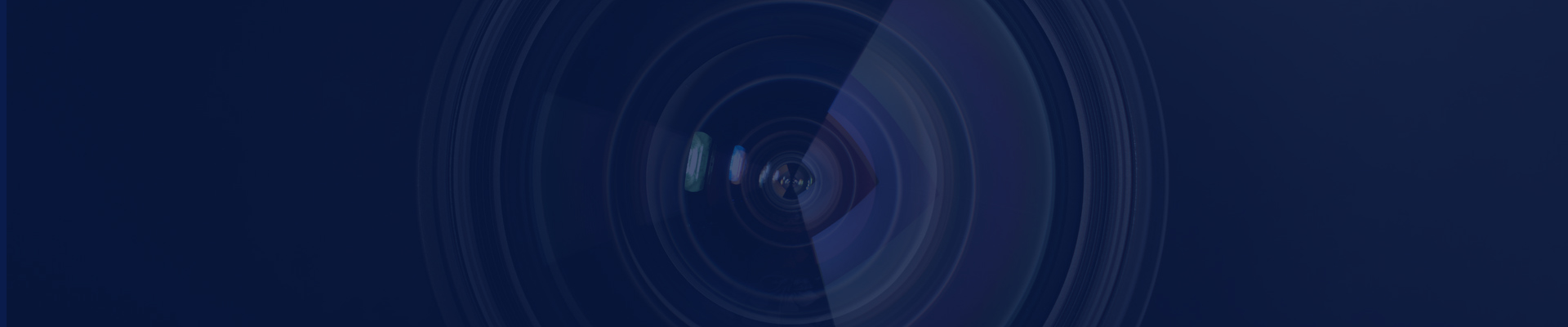

Defects Description

Double wire\Crossing wire\Bonding pad offset, may cause electrical short after packaging.

Missing wire\Broken wire\No pad, may cause may cause electrical break after packaging.

Inspecting particals\Scratches\Cracks on die and wire sagging\Tight wire, may reduce the risk of packaging.

Cases

Camera module | VA6H-17B1@L3D00XW |

Inspectable chip | Gold wire diameter:≥18μmμm |

Spacing:2 times wire diameter | |

Number of layers:≤2layer | |

Inspectable chip size | ≤5mmx5mm |

Wire height | 100μm≤H≤600μm |

Inspection accuracy | Pass inspection rate:≤0.1% |

Missed detection rate:≤0.1% | |

Inspection efficiency | UPH≥20000pcs |

Application

Project testing requirements

| Project name | Defect Inspecction |

| Product Description | Tray plate: 143×67mm² |

| MEMS chip: 4×1.5mm² | |

| Gold wire: diameter 17.78μm, wire height 410~440μm | |

| Full page: 720 chips | |

| Description of Requirement | Inspect gold wire defects:Double bonding /Bonding pad/ offset Broken /wire Scratch / Wire sagging /Crossing wire/ Missing wire /Particles on die /Wire height/Wire tight |

| Demand background | Traditional solutions cannot use three-dimensional information to determine defects and cannot quantitatively detect height information. |

| Project status | December 2020, communication needs |

| In March 2021, it will be put into verification | |

| In November 2021, the first set of verification passed | |

| December 2021, batch delivery | |

| Product solutions | Gold wire detection solution |

| VS2-00@L0D85CG and VA6H-17@L3D00CG | |

| Inspection efficiency | 20000UPH |

| Product operation status | Running stably so far |

Project environmental standards

| Content | Parameter requirements |

| Flatness of incoming materials | 1) Vacuum adsorption; 2) Product corner positioning pins; 3) Front pressure plate; The height difference of the four corners of the sample is < ± 30 μm; |

| Camera motion control | The camera can move in the Z direction with a repetition accuracy of<1 μ M |

| Camera&Light Source Trigger Control | Trigger the camera to capture images through PLC; Response time<10ms; |

| Working vibration | The exposure time of the camera is about 1ms; There is no shaking in the screen |

| operating system | The graphics card driver is the latest version during on-site debugging |

| Industrial computer requirements | Equipped with NvidiaRTX3060 graphics card |

Project Video

TOP

TOP Contact

Contact

Product

Product