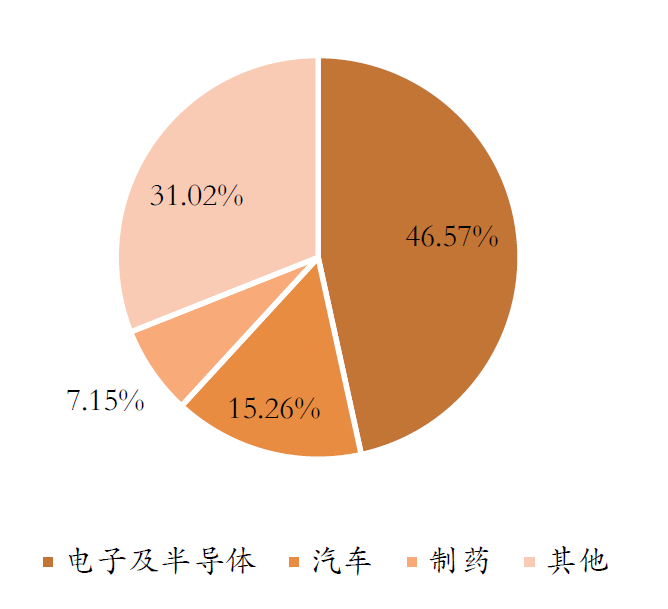

The semiconductor and electronic equipment manufacturing industry is still the most important application field of industrial vision, and it is also the most important driving force for the development of the global industrial vision market. From the perspective of foreign machine vision applications, 46.57% are concentrated in semiconductor and electronics industries; From the global industrial vision leader Cognex's 2017 annual report disclosure data, consumer electronics is also the most important source of revenue, accounting for 40%. Sales in Asia rose 63 percent and in Europe 40 percent, also driven by consumer electronics.

Machine vision application field distribution

Although industrial vision developed earlier in the semiconductor and electronics industry, it has occupied half of the entire industrial vision market. However, based on the technical characteristics of industrial vision and the manufacturing needs of the semiconductor and electronics industry itself, we believe that the semiconductor and electronics industry will still lead the development of the industrial vision industry for a long time in the future.

From the perspective of manufacturing process, there is a rigid demand for industrial vision in semiconductor and electronic equipment manufacturing. Industrial vision has the characteristics of high precision, naturally suitable for high-performance, precision professional equipment manufacturing, which is why related industries can drive the rise of the entire industrial vision. In the field of semiconductor manufacturing, the pre-middle process requires industrial vision precision positioning and visual measurement, and the post-process wafer electrical inspection, cutting, AOI packaging, testing and other processes require a large amount of industrial vision technology, and industrial vision has obvious advantages in speed and accuracy in the semiconductor manufacturing process. In the field of 3C manufacturing, the manufacturing links of components and the main body also need the assistance of industrial vision, of which 70% of industrial vision units are applied in the detection link of machine vision units. In addition, connector detection, PCB negative inspection, hard disk detection, robot visual guidance and positioning, element online classification and screening, two-dimensional code reading, etc., also need industrial vision. Due to the high requirements of technical processes, there is a rigid demand for industrial vision technology in semiconductor and electronic equipment manufacturing.

From the application situation, the degree of automation of China's electronic equipment manufacturing industry is still relatively low compared with developed countries. According to the number of jobs announced in March 2018, the number of employment in China's 3C equipment manufacturing industry reached 8.32 million, which is much higher than other downstream application fields, but the degree of automation is not high. China has concentrated 70% of the world's 3C product production capacity, but the density of industrial robots in 2015 was less than 20 units/million people, while Japan and South Korea have reached 1180 and 1100 units/million people, respectively. Compared with the industrial robot density of the automotive industry has been close to half of the developed countries, China's 3C industry automation upgrade space is larger, industrial vision will also be sustainable development.

Visual inspection system is the "eyes" of industrial automation production, which plays a pivotal role in consumer electronics, semiconductors, automobiles, intelligent security, health care and other industries, and the annual growth rate of the market size is about 20%. In 2019, the national and global machine vision market size exceeded 12 billion yuan and 10 billion US dollars, respectively, and was basically monopolized by the two giants of Cognex of the United States and Keynes of Japan. On the one hand, machine vision is the basic core technology of intelligent manufacturing, reducing import dependence and achieving autonomy and control is the only way to achieve China's national strategy of intelligent manufacturing. On the other hand, the demand for visual inspection is rapidly changing from two-dimensional to three-dimensional, especially due to the iterative upgrading of products in consumer electronics, semiconductors and other fields, more stringent requirements are put forward for three-dimensional defect detection of glass and transparent flexible films, and three-dimensional dimensional detection of tiny precision electronic and metal parts. Traditional two-dimensional and three-dimensional visual inspection technologies are facing huge difficulties. The market calls for new technologies and new solutions to meet new challenges. It is the vision and mission of Yimu Technology to create an autonomous and controllable eye of intelligent manufacturing and fill the gap of "transparent, thin and micro" three-dimensional detection technology.

VOMMA has become the world's second, exclusive domestic light field camera optical design, packaging and manufacturing, light field image 3D rendering, 3D precision and rapid detection of all the core technologies of light field 3D imaging technology company.

TOP

TOP Contact

Contact

Product

Product