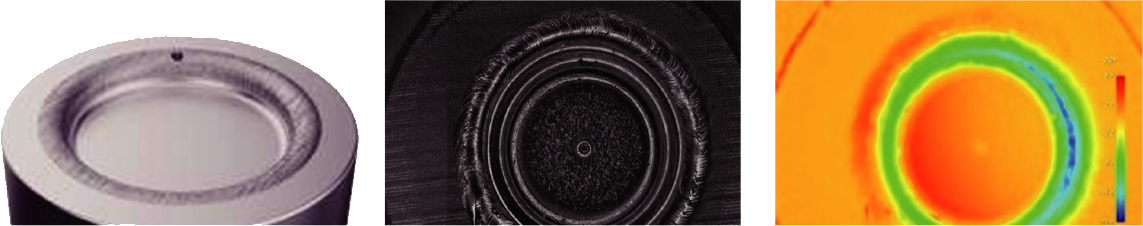

Power battery defect inspection

Batteries are the core components of electric automobile, and the safety of batteries directly affects the driving safety of the vehicles. By inspecting the welding process defects of electric automobile batteries, such as the presence of weld points, pinhole welding pits leading to unreliable weld points, etc., it is possible to detect potential safety hazards in the batteries. This ensures that the vehicle will not experience safety incidents during operation due to battery issues.

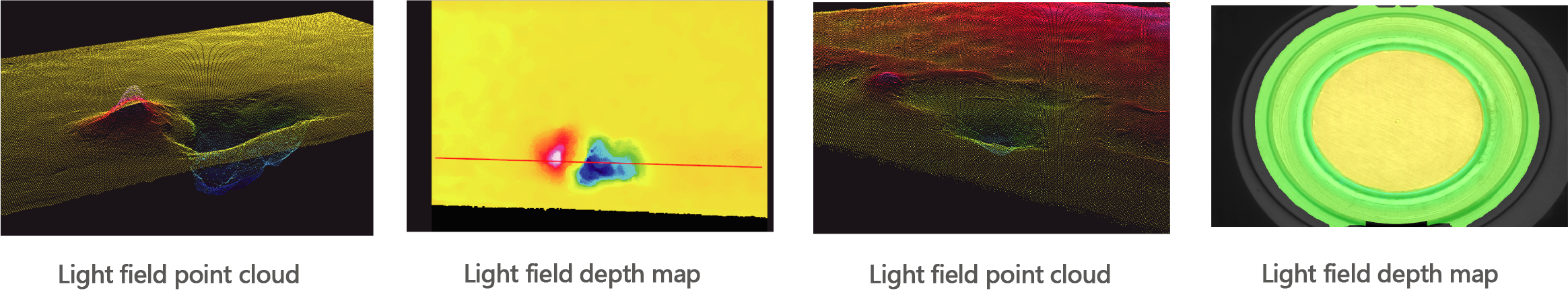

Cases

Application

| Camera module | VA6H-17B1@L1D00CG |

| Inspectable battery defect type | Power battery weld route inspection |

| Pin hole | Diameter≥0.2mm |

| False solder | Width≥0.8mm |

| Raised nail | Height difference≤0.1mm |

| Dent | Depth≥0.2mm Area ≥0.2mm² |

| Weld slag | ≥0.3mm detected |

| Offset welding | Concentric distance ≤0.3mmφ13mm-φ16mm |

| Surface cracks | Length <0.5mm |

| Burn injury | Area ≥0.25mm detected |

| Welding height | Weld height beyond φ13mm is detected in the assembly area |

| Inspection accuracy | 10μm |

| Inspection efficiency | 75ppm |

Solution video/picture

TOP

TOP Contact

Contact

Product

Product